Virtual reality project goes underground for pipeline safety

Enbridge, Microsoft, Finger Food Studios create ‘digital twin’ showing pipeline fitness

Sometimes it’s hard to see the forest through the trees.

And for this particular analogy, those trees are millions of data points along Enbridge’s pipeline network—collected and reported by in-line inspection (ILI) tools, strain gauge sensors, and LiDAR (Light Detection and Ranging) remote sensing systems.

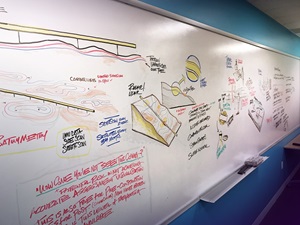

“Enbridge is quite diligent about using overlapping inspection and prevention techniques to diagnose pipeline fitness. But the challenge lies in the fact that there is no way of quickly and effectively visualizing all of the data that’s collected,” notes Tony Khoo, manager of Enbridge’s advanced analytics team.

“Much of the information exists as Excel files, and becomes a struggle for our pipeline engineers to visualize multiple data sets—and understand the underlying data relationships to one another.”

To save our pipeline integrity engineers countless hours in poring over reams of data, representatives of Enbridge, Microsoft and Port Coquitlam, B.C.’s Finger Food Studios went back to the innovation drawing board.

The result is a vital first step toward creating a “digital twin” for Enbridge’s vast pipeline network.

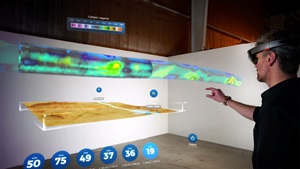

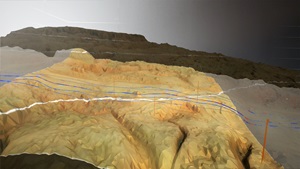

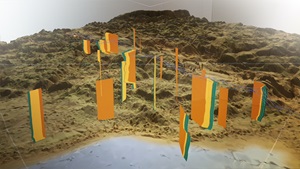

This augmented/mixed reality setting provides a 3D rendering of pipeline sections—demonstrating the ability to process vast quantities of data, and present the information in three dimensions. As a result, users are able to better pinpoint potential hazards in the pipe—including small dents, cracks, areas of corrosion, and pipeline strain caused by incremental ground movement.

“Encouraging innovation is a vital component of directing our own future,” says Trevor Grams, director of Enbridge’s Research Development and Innovation (RDI) unit. “It’s about more than just striving for incremental improvements in the work we do. Innovation is about looking differently at what we need to achieve, and asking how else we can get there.”

As a proof-of-value, the project merged 132 separate sets of pipeline data, as well as terrain information, to create a mixed reality environment depicting a 2.25-square-kilometer area in northern Alberta encompassing an Enbridge pipeline right-of-way.

Image gallery: 3D holographic pipeline 'digital twin'

Wearing Microsoft’s HoloLens glasses, users would be able to rotate, zoom and expand on the virtual image of the pipeline. Areas of concern along the pipelines are then depicted via heat map, with users able to view the various measurements, such as geological forces, and see changes as they occur over time.

Results of the project were presented at an American Petroleum Institute (API) pipeline conference in July 2017.

“Such an application simply doesn’t exist in the pipeline industry,” notes Khoo. “If we are able to fully develop this solution, we would consider offering this to the pipeline industry in the interest of improving overall safety.”

Adds Enbridge’s RDI technology manager Chris O’Neill: “Technologies such as augmented reality have the potential to literally change the way we look at our system, and help us begin to appreciate the wider innovative potential when we treat data as an organizational asset.”

Enbridge’s advanced analytics team is currently establishing partnerships to help build organizational muscle in the augmented reality arena. In other industries, benefits have included:

- Reduced design processes;

- Improved training; and

- Reduced maintenance costs.

“By leveraging such visualization technologies, our engineering teams have the potential to improve speed, understanding and collaboration in their decision making,” says Khoo.

“Using our advanced analytics as a foundation, we would continue building toward our vision of intelligent operations and maintenance of our energy assets.”