Pipeline welding technology: No. 1 of 13

Pipeline welding technology: No. 2 of 13

Pipeline welding technology: No. 3 of 13

Pipeline welding technology: No. 4 of 13

The heart of Enbridge’s business is the pipe in the ground—and the craftsmanship that keeps it strong. Enbridge uses the best available welding technology on our pipeline projects, like the Line 3 Replacement Program (L3RP).

Pipeline welding technology: No. 5 of 13

Pipeline welding technology: No. 6 of 13

Pipeline welding technology: No. 7 of 13

Pipeline welding technology: No. 8 of 13

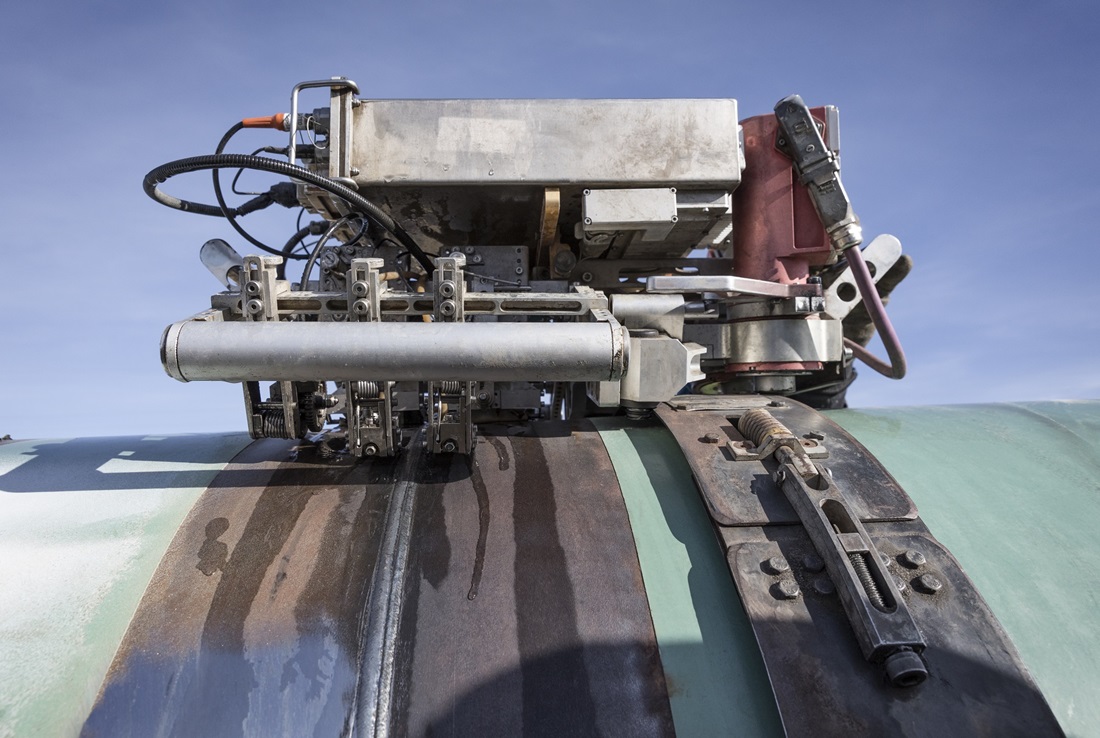

An external unit or “bug,” circling the pipe on tracks, performs several passes from the exterior of the pipe to complete the weld and fill the ¼-inch gap. These “fill” and “cap” passes are performed in portable shacks that offer protection from the elements.

Pipeline welding technology: No. 9 of 13

“There might be five or six shacks following the internal bug, and they just keep hopscotching down the line once they finish a weld,” says Joel McKim, a senior construction specialist on the Line 3 replacement project.

Pipeline welding technology: No. 10 of 13

Pipeline welding technology: No. 11 of 13

Pipeline welding technology: No. 12 of 13

“Enbridge has an internal requirement that a certain percentage of our girth welds out in the field are delay-inspected—for enhanced quality assurance," says Andy Duncan, Technical Services Manager with Enbridge’s Major Projects group.