Hydrostatic testing

Enbridge operates the largest and most complex liquids pipeline system in the world. The integrity and reliability of our pipeline system is our number one priority, and serves to protect the landowners, tenants, communities, and environments along our pipeline right-of-way. Preventative safety measures, such as hydrostatic testing, are crucial to the maintenance of our pipeline system and prevention of future incidents.

Our comprehensive safety measures begin with quality materials and continue with high quality design and construction standards, hydrostatic testing prior to operating new pipelines, as well as employing 24-hour computerized pressure monitoring, routine route surveillance, and promoting on-going industry-leading integrity and maintenance programs.

What is hydrostatic testing?

Hydrostatic testing is a carefully planned and controlled process that gives Enbridge an opportunity to confirm a threshold measurement for safe operations, according to federal regulatory standards. A hydrostatic test is performed following all new pipeline construction, prior to placing a pipeline into service and can also be performed on existing pipelines already in service to confirm pipeline integrity and shipping capacity.

What are the steps involved in hydrostatic testing an existing pipeline?

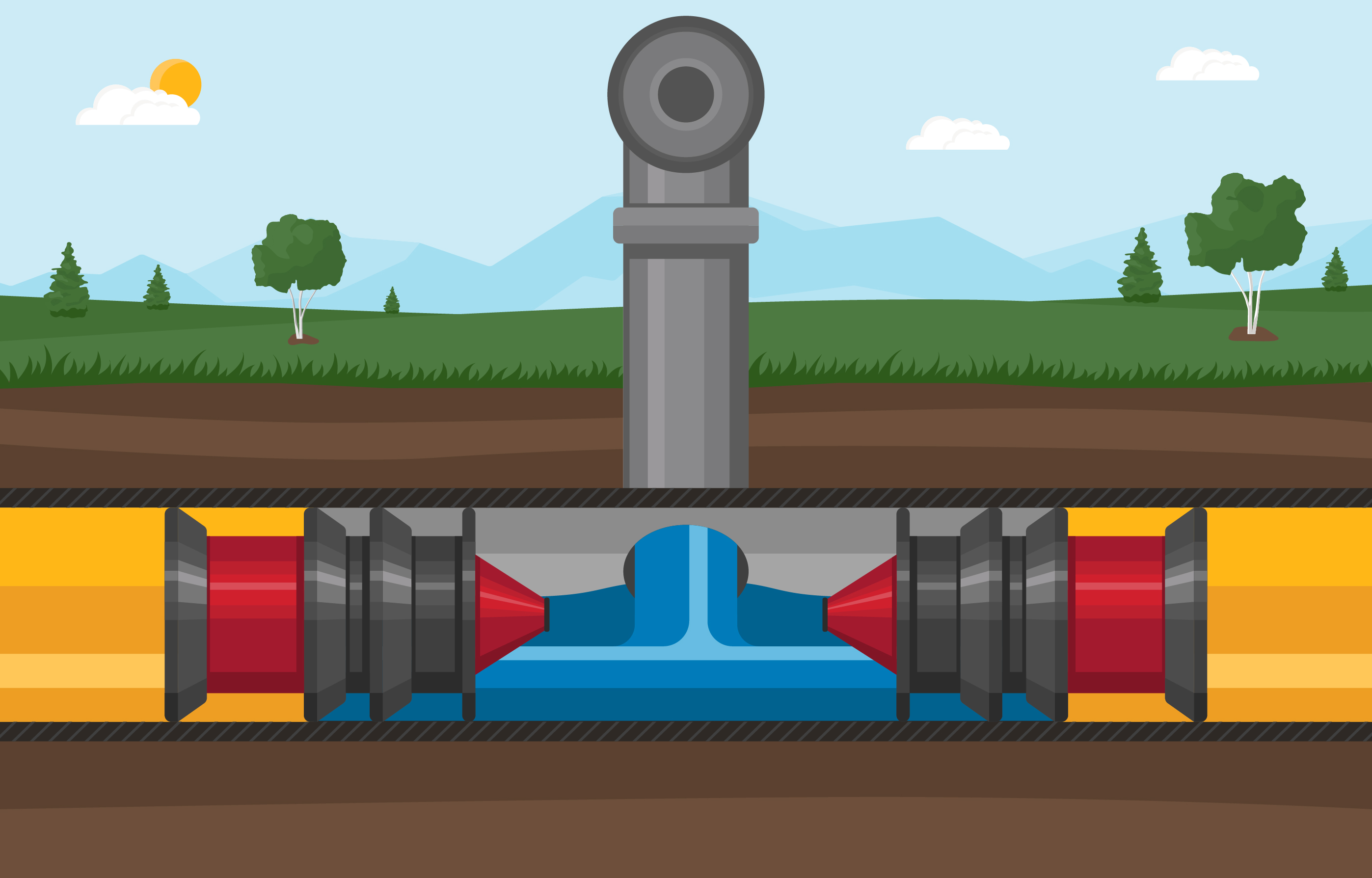

Step 1: Water dyed using a water-soluble, biodegradeable green dye, is injected into the pipe between batches of oil being transported as part of normal operations. The water and oil are separated and sealed from each other by urethane cylinders (referred to as “pigs”), and then the batch is moved through the line until it reaches the identified segment of pipe for testing.

Step 2: The pressure of the tested segment is then raised to reach and maintain the desired test levels and time period. If there is a release of water during the test, it is located, and the affected section is repaired and re-tested. Should there be a release of water during the test, water may briefly spray into the air or pool on the ground.

Step 3: During the testing process, the segment of pipeline under pressure is patrolled by helicopter as well as on foot. Pressures are monitored using sophisticated computer data programs.

Step 4: Following the test, the water is transported down the pipeline to an Enbridge facility, typically into a tank at one of our terminals. The water is cleaned, treated, and disposed of in accordance with local, state, and federal regulations and/or environmental permits.

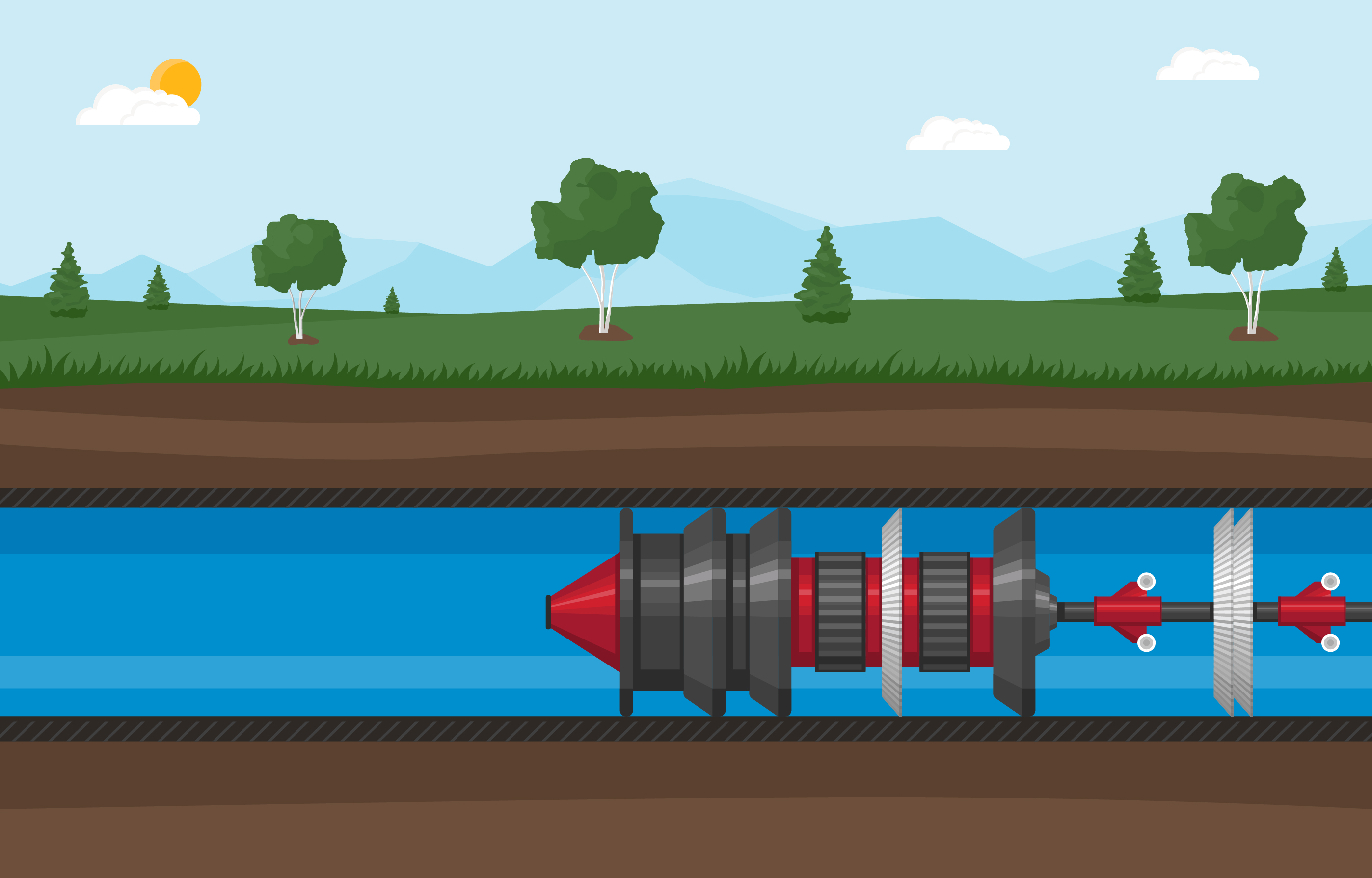

Step 5: Internal inspections of the pipeline using “smart pigs” provide additional data on the pipeline’s condition as well as removing remaining water and other potential contaminants.

Step 6: Any exposed area of pipe that was accessed during the test is backfilled, and property is restored.

Step 7: Normal shipment of North American crude oil resumes in the pipeline to be safely delivered to refinery customers and made into products we all depend on in our daily lives.

What to expect

Landowners and tenants along the pipeline route will be notified by letter announcing the test dates and general location of the pipeline segment being tested. During the actual test period, signs will be posted along public access areas and ads will run in local papers near the segment of pipeline being tested.

Landowners and tenants along the pipeline route can expect the following:

- Temporary work activity along the pipeline route;

- Temporary elevated noise levels in the limited locations where test equipment is set-up and where personnel are working; and,

- Work may occur at night as well as during the day in order to attain the prescribed duration, typically a minimum of eight sustained hours at required pressure. However, few landowners and tenants will be affected or notice much change from normal activity levels.

Public awareness and safety

Signs are posted at public access points along the testing area to keep the public at least 100 feet away from the pipe during the test.

If a pipe fails during the test, the pressurized testing water may briefly spray into the air and eventually pool on the ground. Do not go near the release.

Pipeline crews will be monitoring the line; however, should you discover a rupture or a pool of colored water on the ground near a test site, please call 1-800-858-5253. Enbridge crews will respond immediately.