Supply Chain Management

Overview

We work with suppliers to advance our sustainability performance.

For Enbridge, our supply chain―those organizations that provide materials, goods or services to Enbridge, including contractors, subcontractors, vendors and consultants―plays a key role in our ability to live up to our social responsibility commitments and attain our sustainability objectives. To that end, we strive to work with suppliers who are leaders in their industries; are willing to uphold our core values of integrity, safety and respect; adhere to our fundamental policies and procedures and the Enbridge Statement on Business Conduct; and share our commitment to the highest standard.

Moreover, the creation of opportunities for Indigenous socio-economic participation continues to be integral to our Supply Chain Management (SCM) strategies and management systems.

4 performance objectives:

- Procuring goods and services that meet our standards for environmental stewardship

- Expanding opportunities for participation of local, small and minority-owned businesses in our supply chain

- Expanding opportunities for Indigenous socio-economic participation in our supply chain

- Procuring goods and services that meet our standards for safety and ethical practice

2017 Highlights

Acquired nearly $11.6 billion in goods and services company-wide from about 19,000 suppliers

Spent approximately 44% with Canadian suppliers, 56% with U.S. suppliers

Purchased about 133,000 tonnes of steel pipe, about 87% of which was made from recycled steel

Spent more than $216.8 million with Indigenous businesses, contractors and suppliers in Canada and the U.S

Management Approach

We work with thousands of suppliers across North America—from major international companies to small, local businesses. Our suppliers cover a wide range of disciplines, including manufacturing, construction, engineering, distribution and consulting, but the majority of our annual spend is in the areas of pipe manufacturing, constructing our pipelines and facilities, maintaining the fitness of our systems and monitoring to ensure the integrity of our systems.

Safety and opportunities for Indigenous involvement are two major considerations in our contract evaluation process, and we have a centralized SCM team and multi-year roadmap to help us further integrate Indigenous socio-economic participation and other environmental, social and governance (ESG) considerations and opportunities into our SCM strategies and programs. In 2017, we integrated key elements from Spectra Energy’s SCM CSR approach, providing a unified framework and roadmap going forward.

SCM Structure

We have one, centralized SCM function serving the entire enterprise. It is responsible for all aspects of SCM—from planning and governance, to tactical procurement and materials management, to contract management and strategic sourcing—with the goal of creating maximum value for Enbridge and our stakeholders. Our SCM function also has a centralized team to help us further integrate Indigenous participation and other environmental and social considerations and opportunities into our SCM strategies and programs.

SCM Governance

Enbridge’s core values of integrity, safety and respect, as well as a number of specific policies and protocols, govern all of our SCM function’s activities, and we continue to update and improve these policies as our business expands. Examples include these governing documents: Statement on Business Conduct, Corporate Social Responsibility Policy, Indigenous Peoples Policy, SCM Policy and Purchasing Controls Policy as well as a Supplier Code of Conduct, which we expect to publish the second half of 2018. (Update: The Supplier Code of Conduct is now available.)

How SCM Integrates Environmental, Social and Governance Factors

Our SCM processes are designed to procure goods and services that meet our standards for environmental stewardship, social responsibility and ethical practice. We satisfy this objective by integrating ESG factors into our supplier selection and relationship management through a variety of means, including pre-qualification, requests for proposal (RFPs), proposal evaluations, contracts and supplier performance management.

Pre-qualification – In 2017, we implemented an updated pre-qualification process as part of the Supplier Lifecycle Management process. Roll-out and additional improvements to the process will continue through 2018 and 2019. In addition to ongoing core requirements related to safety and Indigenous participation, these enhancements will address other environmental and social considerations.

In the new process, we continue to use ISNetworld (ISN), a global resource for connecting corporations with reliable contractors and suppliers and pre-qualifying them on the basis of safety. We also continue to engage subject-matter experts from all relevant areas of Enbridge―including technical, legal, finance, etc.―to provide input into supplier pre-qualification and the monitoring phases of the supplier lifecycle, as well as to provide guidance on emerging issues. They also ensure that our standards regarding safety, quality, labor and environmental practices are upheld throughout our supply chain.

Also in 2017, we updated the Supplier Information Form on our website to gather basic ESG information from potential future suppliers.

RFPs, Proposal Evaluations, Contracts and Supplier Performance Management – Our SCM function has developed content to address safety, sustainability and Indigenous participation factors that it includes in its RFPs, proposal evaluations and contracts. In 2017, our SCM function began including sustainability factors in its supplier performance management processes. These efforts will continue to expand in 2018 and 2019.

Risk Management Considerations – To manage the sustainability risks among our suppliers, our SCM function considers multiple business factors that relate to sustainability, including:

- environmental standards associated with our suppliers’ processes, products or services;

- fundamental human rights (e.g. freedom of association and promoting an inclusive and respectful workplace);

- occupational health and safety;

- business ethics (e.g. corruption and anti-competitive practices);

- quality of management systems; and

- sub-contractor guidance (i.e. whether suppliers require their sub-contractors to adhere to supplier standards).

Sustainability is a high priority for Enbridge, and we believe the thousands of suppliers who work with us across North America can help us advance those priorities.

That’s what inspired Joel Adams, Enbridge’s Supervisor, Warehousing and Logistics in Duluth, Minnesota to bring suppliers in his region together to talk about sustainability collaboration.

“I’m very proud of Enbridge’s efforts to promote sustainability,” said Adams, “and I wanted to share our goals with our suppliers. I also wanted to learn how others are growing and supporting sustainable operations.”

His vision became a reality in November 2017, when 45 people representing regional businesses that supply goods and services to Enbridge gathered in Duluth for our first U.S. Supplier Sustainability Summit, which included presentations on sustainability at Enbridge and break-out sessions where suppliers shared their leading sustainability practices and brainstormed potential environmental stewardship opportunities that could benefit both Enbridge and them.

Feedback from attendees was positive, with many noting a greater understanding of Enbridge’s expectations for environmental stewardship, social responsibility, ethical procurement and Indigenous engagement within the supply chain. Commented one supplier: “I appreciated that Enbridge took the time to present this topic to a broad audience, many of whom were candid in that they hadn't thought all that much about these topics previously. For myself, I came away with some new ideas on how to reduce consumption in several areas.”

As a follow-up to the summit, Enbridge met with several attendees to further discuss how their products, service offerings and ideas may contribute to Enbridge’s and their own sustainability goals. And looking ahead, we plan to hold more sustainability summits for suppliers in the future.

“With this summit, we wanted to start the conversation about sustainability with suppliers who are beginning their efforts and to continue the conversation with suppliers that have proficiently implemented sustainability principles already,” said Charlene Uecker, Enbridge’s Technical Manager, SCM Sustainability. “No matter where companies are on the journey, we can learn from each other and improve together. Enbridge highly values our supplier relationships and recognizes the critical role they have in our sustainability journey.”

In addition to the U.S. summit, Union Gas’s 2017 Supplier Forum in Canada featured Indigenous engagement as a key topic with a keynote speaker from the Canadian Council for Aboriginal Business.

2017 Performance

2017 Company-wide Procurement

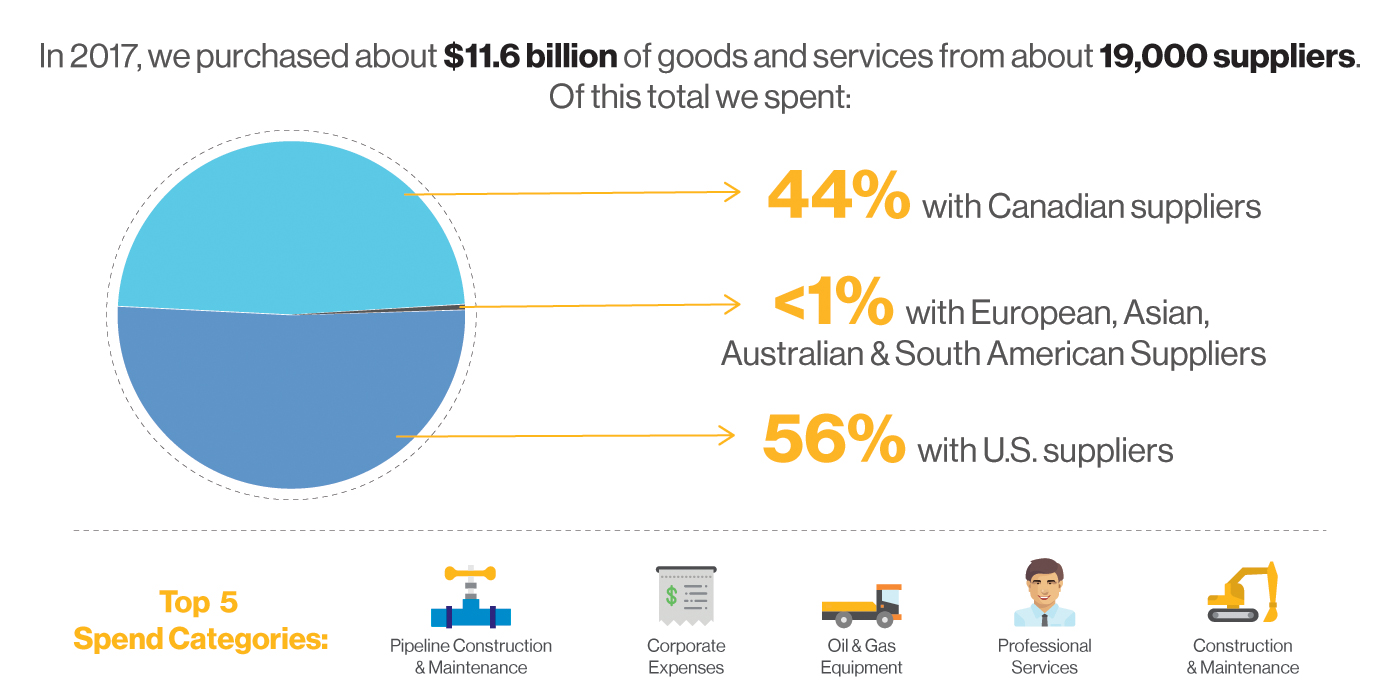

In 2017, we purchased about $11.6 billion of goods and services from about 19,000 suppliers. Of this total, we spent about 44 percent with Canadian suppliers, 56 percent with U.S. suppliers and less than one percent with European, Asian, Australian and South American suppliers.

In 2017, we purchased about $11.6 billion of goods and services from about 19,000 suppliers. Of this total, we spent about 44 percent with Canadian suppliers, 56 percent with U.S. suppliers and less than one percent with European, Asian, Australian and South American suppliers.

Procuring goods and services that meet our standards for environmental stewardship

Strong supplier relationships are important to our business success. We believe in doing business with suppliers who demonstrate high standards of ethical business conduct and who share our commitment to safety, reliability and quality.

Recycled Steel Pipe

Our SCM function’s most significant materials purchase is steel pipe. In 2017, we purchased about 133,000 tonnes of steel pipe, about 87 percent of which was made from recycled steel.

| Amount of Steel Pipe Purchased (tonnes) / Percentage of which Was Made from Recycled Steel | |||

|---|---|---|---|

| 2015 | 2016 | 20171 | |

| Major Projects1 | 220,508 / 96% | 324,000 / 96% | 119,200 / 94.9% |

| Enbridge Gas Distribution | 1,243 / 63.8% | 793 / 60.7% | 1,624 / 88.8% |

| Union Gas | N/A | N/A | 12,130 / 11.9% |

| Total | 132,954 / 87.3% | ||

12017 reflects Spectra Energy and Enbridge assets as a combined company

Enbridge Gas Distribution (EGD) and Union Gas in Ontario have the largest natural gas vehicle (NGV) fleet in Canada, and we have converted most of the vehicles to run on natural gas. This has resulted in lowering the carbon footprint for this fleet, reducing fuel costs and promoting the use of natural gas in the transportation sector.

Every RFP that our SCM function issues to vehicle manufacturers on behalf of EGD requires that the supplier provide vehicles that are either NGV ready or that have a component for conversion to NGV. For more information, please see the Climate Change section of our Sustainability Report.

Procuring goods and services that meet our standards for safety and ethical practice

We are committed to buying from companies that uphold the Enbridge’s Statement on Business Conduct and will not compromise on our core values of safety, integrity and respect. Our SCM processes—from pre-qualification to contracting—hold our suppliers accountable to our standards and requirements for safety and ethics. Additionally, in 2017 building upon the Supplier Code of Conduct that Spectra Energy previously implemented, we began to develop a new Supplier Code of Conduct that outlines the company’s expectations regarding the ethical standards and business conduct of our suppliers within these areas: health and safety; the environment; labor and human rights; and responsible business behavior. We expect to implement it by the end of 2018.

Suppliers who have questions or concerns about compliance and ethics issues are encouraged to use the Enbridge Ethics and Conduct Hotline, and all calls to the Hotline are treated in strict confidence according to Enbridge’s Whistleblower Policy which also prohibits retaliation against any person making a complaint in good faith.

Human trafficking is modern-day slavery, a crime that occurs whenever people are bought or sold for forced labor or sexual exploitation. It is more than a North American problem; the International Labour Organization estimates that globally, about 25 million people are victims of trafficking.

Enbridge recognizes that human trafficking is a real and important problem, and we stand strongly against this exploitation. To do our part to fight human trafficking, Enbridge proactively informs its employees, contractors and suppliers of the resources available that describe trafficking behaviors to watch for and contact phone numbers to report these behaviors, if observed. For example, the advocacy organization, Truckers Against Trafficking (TAT), provides an educational video, downloadable cards and phone numbers to help truck drivers in North America combat human trafficking.

Our Supply Chain Management team is working within our transportation and logistics network to advance TAT training. At our Gas Transmission & Midstream business unit, 56 percent of our carriers are now TAT trained, and in 2018, we are looking to train up to 75 percent of our carriers. Also in 2018, SCM will roll out the TAT training at our Liquids Pipeline warehouses.

Enbridge has also raised awareness on human trafficking for our employees by hosting events with guest speakers. In 2017, the Freedom Drivers Project visited the Houston office as a part of an event. This traveling exhibit is designed to help educate the public about the realities of human trafficking and what the trucking industry is doing to combat it.

We are planning to replicate these activities in other regions in our operational footprint in 2018.

Expanding opportunities for Indigenous socio-economic participation in our supply chain

Enbridge’s SCM function has a team within it that is specialized and dedicated to proactively facilitating opportunities for Indigenous communities within our supply chain. In 2017, we continued to build on our prior work in this area, increasing our resources and results in both Canada and the U.S.

Because a significant opportunity within our supply chain is sub-contracting, we created and implemented tools for our prime contractors to seek and incorporate Indigenous participation in their work with Enbridge. These tools include the Socio-Economic Requirements of Contractors (SERC) and access to our database of quality Indigenous businesses.

In 2017, our Indigenous business database for Major Projects and Liquids Pipelines increased about 40 percent with significant effort to develop a database for the U.S., and our Union Gas Indigenous business listing was overhauled and enhanced. Additionally, we expanded the SERC from Major Projects work to incorporating it in some of our existing Liquids Pipelines preferred supplier agreements. We also began incorporating Indigenous inclusion in the supplier relationship management process and supplier performance indicators with preferred suppliers.

For more information, please see the Indigenous Engagement section of our Sustainability Report.

As everyone who lives in a cold climate well knows, it’s imperative to prepare your home for the onslaught of winter so that you and your family stay safe and warm.

As Canada's largest natural gas distributor, Enbridge also knows that for some of our customers, finding the money needed to weatherize their home can be a challenge. In response, our Union Gas utility in Ontario developed their Home Weatherization Program (HWP) to provide their low-income customers living in older, single-family homes with a range of services free of charge—everything from energy audits and water-saving measures, to a programmable thermostat, a carbon-monoxide detector and insulation installation.

In 2016, Union Gas expanded the program to cover 20 Indigenous communities in their franchise area over the next four years. They also modified the program to provide a smoke alarm for every home in these communities—regardless of whether or not they are a Union Gas customer—because many Indigenous homes go without this basic life-saving tool and because safety is at the forefront of everything we do at Enbridge.

In 2017, year one of the program, Union Gas aimed to deliver the HWP to four Indigenous communities in Ontario—Garden River First Nation (Sault Ste. Marie); Batchewana First Nation (Sault Ste. Marie); Nipissing First Nation (North Bay); and Mississauga First Nation (Blind River). Nearly all of these communities participated in the program’s application process, a level that is higher than off-reserve participation. Overall, we found in the initial energy assessments that more homes than expected were weather tight, and as a result we did not weatherize as many homes as we had planned. Despite this, these communities provided positive feedback about the program.

Also in 2017, Enbridge’s Supply Chain Management team identified an opportunity to add a qualified and competitive Indigenous business to the HWP roster of contractors—First Nations Engineering Services Ltd. (FNESL)—which is now contributing its technical expertise, as well as meeting the program’s expectations for safety and customer service.

In 2018, we plan to advance the program to four more Indigenous communities: Mohawks at the Bay of Quinte First Nation (Belleville); Long Lake #58 First Nation (Longlac); Ginoogaming First Nation (Longlac); and Atikameksheng Anishnawbek First Nation (Sudbury).

Also starting in 2018, we now have the opportunity to co-deliver the program for Indigenous communities with Hydro One, Canada’s largest electricity transmission and distribution service provider, because both Union Gas’s HWP and Hydro One’s Aboriginal Conservation Program share FNESL as our delivery agent. In early 2018, at the Mohawks at the Bay of Quinte First Nation, we launched a pilot program for the combined delivery approach, which benefits customers by reducing the number of home visits, as well as wait times for Union Gas’s and Hydro One’s respective programs.

By expanding their Home Weatherization Program to serve Indigenous communities, Union Gas has enhanced their relationships with our Indigenous partners, improved collaboration through interaction with Chiefs and Councils, and enhanced our outreach to these communities overall. And with FNESL on board, we have also rounded out the professional experience within our contractor base as we continue to deliver the energy that people need and want.

Indigenous socio-economic participation in our projects is a priority for Enbridge. We have long recognized that hiring Indigenous businesses and contractors supports local employment, gives us the opportunity to understand available services and talent, and helps us build trust and relationships.

As part of these efforts, we also work closely with companies in our supply chain to help us expand opportunities for Indigenous socio-economic participation.

In 2017, Enbridge began work to replace and reroute a 3,500-foot (1,067-meter) section of our existing Line 4 around the northern edge of Nushka Lake near Bena, Minnesota. The project was entirely within Leech Lake Band of Ojibwe tribal lands, so Enbridge contacted tribal officials to first discuss the project and request permitting. At the same time, Enbridge’s SCM Indigenous Engagement team worked with the Leech Lake band’s Tribal Employment Rights Ordinance (TERO) Director to ensure we followed all tribal TERO rules, which require that all employers who are engaged in business or have a construction project within tribal lands give preference to qualified tribal members and pay a certain percentage of construction costs to the tribe’s training program.

As a result, 16 band members worked during the project, providing direct economic impact to Leech Lake communities, plus giving opportunities to tribal members for work experience and union membership. In addition, the Line 4 project had the support of the tribal government.

“Our efforts with the Leech Lake band demonstrate that engaging with tribal communities early and continuously regarding projects and economic development is a model for success,” says Enbridge’s Gail Wahlberg, Specialist, Indigenous Engagement. “The positive relationships that this project has fostered between the Leech Lake band and Enbridge have proven to be invaluable. I couldn’t be more proud of our team’s work executing the project!”

An important part of that team was one of our major suppliers in Minnesota—United Piping Inc. (UPI), an oil and gas industry general contractor headquartered in Duluth. We spoke with UPI’s Mel Olson, President, about the action his company is taking to support Indigenous economic participation.

1) How has UPI worked with Enbridge to advance our commitment to building strong relationships with Indigenous communities?

UPI has been working to create relationships with Indigenous communities in a number of ways. We’ve partnered with our neighbors from the Fond du Lac and Leech Lake Ojibwe tribal communities to conduct hands-on courses in pipeline construction techniques and safety. Twenty-five tribal members gathered at UPI’s corporate office in 2017 for two separate, week-long training events. Our objective was to build relationships between our UPI employees and the tribal communities in our area and to provide the basic skills needed to work on pipeline construction jobs. The training covered the basics of safety, line location, excavation, blasting, coating, painting, and backfilling and restoration, and drew on our experience and knowledge to provide the best possible teaching and experience for our participants.

We also held an extensive week long new-hire training with the Leech Lake Band of Ojibwe in November 2017 in preparation for Enbridge’s Line 4 Nushka Lake project. Fifteen people received orientation, operator qualifications for the project, and hands-on equipment safety training. These events were a first for UPI but not the last, and their success will pave the way for more initiatives and training events that help UPI reach its broader community. We have built relationships with the Leech Lake TERO office and others and will continue to seek out ways to strengthen UPI’s and Enbridge’s commitment to building strong relationships with Indigenous communities.

2) What benefits did UPI realize from the Nushka project?

We were able to provide work for 150 UPI employees on this project. Winter pipeline work provides steady employment for many, and we were thrilled that we could keep these folks working when they may otherwise not be. The man hours spent on this project have surpassed 96,250 hours. We had the opportunity to work with Fond Du Lac Pipeline Services for one aspect of the project, and they did an outstanding job. We also had the opportunity to train and employ new Indigenous union employees, which could be an asset to us in the future. As a result of the Indigenous employment, we now have a larger pool of qualified construction professionals to help us achieve success on future projects.

3) Is there anything else you want to tell us about how our companies work together to advance mutual Indigenous engagement goals?

One of UPI’s top priorities for 2018 is to increase the percentage of Indigenous people available to the pipeline construction industry. In order to meet our goals, we established a formal training program, and we support Enbridge in their engagement goals by supporting tribal trades development initiatives. We look forward to continuing to work with Enbridge to advance our mutual Indigenous engagement goals.

| Dollars Spent on Materials and Services Sourced from Indigenous Businesses in Canada and the U.S. (Canadian dollars) | |||

|---|---|---|---|

| 2015 | 2016 | 20171 | |

| Major Projects and Liquids Pipelines | >$63 million | $79 million | $136.2 million |

| Union Gas | $6 million | $13 million | $10.5 million |

| Gas Transportation & Midstream2 | $70.1 million | ||

| Number of Qualified Indigenous Businesses Identified and Documented in Our Databases / Business Listings | |||

| MP/LP Canada | 600 | 760 | |

| MP/LP U.S. | 100 | ||

| Union Gas | 74 | ||

1 2017 reflects Spectra Energy and Enbridge assets as a combined company

2 in British Columbia only- Capital and Operations

Expanding Opportunities for Participation of Local, Small and Minority-owned Businesses in Our Supply Chain

Enbridge recognizes the value and innovation that results from having a diverse group of suppliers, including woman-owned, minority-owned, small and local businesses; and we promote equal opportunity for all qualified suppliers.

Building on efforts initiated by Spectra Energy, we plan to enhance our approach to supplier diversity. We started tracking diverse supplier data in our Gas Transmission and Midstream business segment in 2017, and we will make similar efforts in our other business segments as part of our three-year roadmap.

| Dollars Spent on Materials and Services Sourced from Diverse and Small Businesses in Canada and the U.S. – Gas Transmission and Midstream (Canadian dollars) | |||

|---|---|---|---|

| 20151 | 20161 | 20172 | |

| Small Businesses (U.S.) | $72.5 million | $67.6 million | $99.6 million |

| Woman-owned Businesses (U.S.) | $5.2 million | $4.8 million | $6.2 million |

| Minority-owned Businesses (U.S.) | $3.5 million | $0.4 million | |

1 Data from legacy Spectra businesses.

2 2017 reflects Spectra Energy and Enbridge assets as a combined company

| Supply Chain Management Data Summary | |||

|---|---|---|---|

| 2015 | 2016 | 20171 | |

| Amount of Steel Pipe Purchased (tonnes) / Percentage of which Was Made from Recycled Steel | |||

| Major Projects | 220,508 / 96% | 324,000 / 96% | 119,200 / 94.9% |

| Enbridge Gas Distribution | 1,243 / 63.8% | 793 / 60.7% | 1,624 / 88.8% |

| Union Gas | 12,130 / 11.9% | ||

| Dollars Spent on Materials and Services Sourced from Indigenous Businesses in Canada and the U.S. | |||

| Major Projects and Liquids Pipelines | >$63 million | $79 million | $136.2 million |

| Union Gas | $6 million | $13 million | $10.5 million |

| Gas Transportation & Midstream2 | $70.1 million | ||

| Number of Quality Indigenous Businesses Identified and Documented in Our Databases / Business Listings | |||

| MP/LP Canada | 600 | 760 | |

| MP/LP U.S. | 100 | ||

| Union Gas | 74 | ||

| Dollars Spent on Materials and Services Sourced from Diverse and Small Businesses in Canada and the U.S. – Gas Transmission & Midstream (Canadian dollars) | |||

| Small Businesses (U.S.) | $72.5 million | $67.6 million | $99.6 million |

| Woman-owned Businesses (U.S.) | $5.2 million | $4.8 million | $6.2 million |

| Minority-owned Businesses (U.S.) | $3.5 million | $0.4 million | |

1 2017 reflects Spectra Energy and Enbridge assets as a combined company

2 in British Columbia

Conversations

1) Please tell us about your organization, as well the benefits of the relationship between Acuren and Enbridge?

Acuren provides state-of-the-art nondestructive testing, inspection, engineering and rope-access-enabled industrial services delivered through over 80 locations and over 4,000 employees throughout North America and the United Kingdom.

Acuren has a longstanding relationship as a service provider to Enbridge that spans decades across a wide variety of projects. Among other services, Acuren’s core service to Enbridge has been a wide array of Non-Destructive Examination services. Our knowledge and experience in providing services to Enbridge on hundreds of scopes of work have allowed our technicians and leadership to form trusted relationships. The depth and length of this longstanding relationship allows us to utilize our experience to drive value for Enbridge. Further, the Enbridge path to zero aligns with Acuren’s safety culture, and Acuren’s exemplary safety record affords Enbridge a level of comfort in knowing that they’ve selected a service provider that ensures safety considerations are the number one priority.

Acuren feels that through developed communication channels we are better suited to understand and meet Enbridge’s requirements, of which we feel have been appreciated through our internal pool and depth of industry experts and technicians, the breadth of our organizational footprint, open access to the regional leadership teams, and commitment to investment in emerging technologies. We look to work together for continued success.

2) How has Acuren worked with Enbridge to advance our commitment to environmental stewardship?

Our shared environmental target is always zero—zero incidents and zero spills. Acuren’s management recognizes an obligation to protect the human, physical and financial resources of our organization and every client site we work on.

We also recognize our responsibility to ensure environmental protection. For each project, we develop an environmental plan and program. These cover each individual and their responsibilities associated with their work for Enbridge. At the heart of the environmental plan is the Environmental Program Coordinator, who is responsible for developing and setting the groundwork for the program to assure compliance with Acuren’s and Enbridge’s policies and procedures, as well as state/provincial and federal regulations. The site lead is responsible for communicating expectations at the site and assuring on a day-to-day basis that the program requirements are being followed. The employees are required to understand the program, as well as identify and understand disposal of various waste products. Employees are also trained and engaged to recognize environmental incidents, immediately implementing appropriate actions and reporting of these events.

3) Over the last three years, Acuren has been methodically replacing film-based radiography with computed or digital methods. What are the environmental benefits of that?

We carry out radiographic testing for a variety purposes, including weld examination, fabrication and repair of tanks, and crack detection. This type of testing detects both surface and subsurface defects, requires minimal surface preparation and provides a permanent record of an inspection.

These newer technologies eliminate the need for chemicals to develop the exposures, which in turn leads to fewer chemical and heavy-metal disposal and recycling programs. In addition, our carbon footprint is cut in half because we can eliminate the need for darkrooms and move to driving smaller trucks, which are more fuel efficient.

4) In what other ways are Acuren and Enbridge working together to contribute to a more sustainable world?

We work together in areas that have a direct impact on sustainability outcomes, including quality initiatives, HSE programs, environmental protection plans, and material management and selection programs. In addition, sustainability is engrained as a part of Acuren’s culture, and that translates into the decisions we make each and every day on any customer site, including Enbridge’s.

Moreover, when companies have a shared philosophy of sustainable, responsible operations like the one Acuren and Enbridge have, it becomes a partnership type of approach. This sort of partnership has the greatest potential to yield the most impactful benefits.